Houston Ready Mix Concrete Suppliers Ready Mix In Houston TX are essential partners when construction deadlines are approaching and project quality is at stake. Selecting the right supplier can mean the difference between success and failure for contractors managing commercial developments, homeowners planning driveway installations, or project managers overseeing infrastructure improvements.

Houston’s construction industry continues to expand rapidly, with annual building permit values exceeding $6 billion. This comprehensive guide covers everything you need to know about Houston ready mix concrete suppliers, allowing you to make informed decisions that will ensure project success, cost efficiency, and long-term durability.

Understanding Ready Mix Concrete: The Foundation of Houston’s Construction Success

Ready mix concrete is a precisely engineered mixture of cement, aggregates, water, and admixtures that arrives on-site ready to pour. Compared to on-site mixing, ready mix concrete provides greater consistency, quality control, and time efficiency.

The typical ready mix concrete batch contains 10-15% cement, 60-75% aggregates, and 15-20% water, with exact proportions depending on the application. Modern ready mix formulations frequently contain chemical admixtures that improve workability, accelerate or retard setting times, and increase resistance to Houston’s harsh environmental conditions.

What Makes Houston Ready Mix Concrete Suppliers Different?

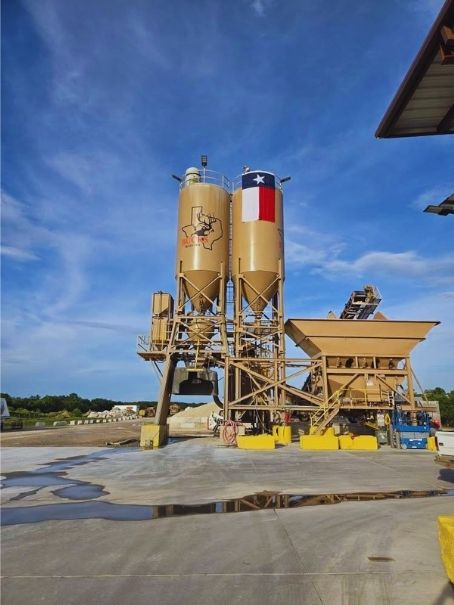

Houston ready mix concrete suppliers face unique regional challenges that set them apart from providers in other markets. The city’s vast geography, spanning over 670 square miles, necessitates strategic plant locations to ensure timely delivery before concrete begins to set. Furthermore, Houston’s soil conditions, which include expansive clays and high moisture content, necessitate the use of specialized concrete mixes that allow for ground movement while preventing cracking.

Leading Houston suppliers have multiple batch plants strategically located throughout the metropolitan area, including Katy, The Woodlands, Sugar Land, and Pearland. This geographic distribution allows suppliers to deliver fresh concrete within the critical 90-minute window from batching to placement, resulting in optimal workability and strength development. Furthermore, top-tier suppliers invest in GPS-enabled mixer trucks and automated dispatch systems to improve routing and reduce delays.

How Do You Choose the Right Ready Mix Concrete Supplier in Houston TX?

Selecting the appropriate ready mix concrete supplier requires careful evaluation of several critical factors. First, verify that potential suppliers maintain current certifications from the National Ready Mixed Concrete Association (NRMCA) and comply with American Concrete Institute (ACI) standards. These credentials demonstrate commitment to quality, safety, and industry best practices.

Second, assess the supplier’s technical support capabilities. Premium suppliers employ experienced concrete technologists who provide mix design assistance, conduct site evaluations, and offer recommendations tailored to your specific application. Whether you’re pouring a residential foundation, commercial parking structure, or decorative patio, expert guidance ensures you order the correct concrete strength, slump, and admixture package.

Third, investigate the supplier’s delivery reliability and fleet capacity. Projects rarely proceed exactly as planned, and the best suppliers demonstrate flexibility in accommodating schedule changes, handling rush orders, and coordinating multiple truck deliveries for large continuous pours. Request references from previous clients and inquire about the supplier’s average on-time delivery rate, which should exceed 95% for reputable providers.

What Are the Most Common Ready Mix Concrete Applications in Houston?

Houston’s diverse construction landscape demands ready mix concrete for numerous applications. Residential projects frequently require concrete for driveways, patios, sidewalks, pool decks, and foundation slabs. Homeowners typically need 3,000 to 4,000 PSI concrete for these applications, with enhanced specifications for decorative finishes or high-traffic areas.

Commercial and industrial projects present more complex requirements. Office buildings, retail centers, and warehouses often require high-strength concrete exceeding 5,000 PSI for structural columns, beams, and elevated slabs. Additionally, specialized applications such as parking garages necessitate air-entrained concrete that resists freeze-thaw damage and de-icing salt deterioration. Industrial facilities may specify fiber-reinforced concrete for floor slabs subjected to heavy equipment loads and abrasion.

Infrastructure projects, including roadways, bridges, and municipal facilities, represent another significant market segment. These applications typically require strict compliance with Texas Department of Transportation (TxDOT) specifications, including specific cement types, aggregate gradations, and performance criteria. Consequently, contractors working on public projects must partner with suppliers approved on TxDOT’s qualified products list.

What Factors Influence Ready Mix Concrete Pricing in Houston?

Understanding ready mix concrete pricing helps you budget accurately and identify competitive rates. Base prices typically range from $115 to $165 per cubic yard, depending on concrete strength, delivery distance, and order volume. However, several factors can significantly impact your final cost.

Concrete strength represents the primary pricing variable. Standard 3,000 PSI concrete costs considerably less than high-strength 6,000 PSI mixes due to higher cement content and specialized ingredients. Similarly, specialty concretes incorporating color pigments, decorative aggregates, or performance-enhancing admixtures command premium prices reflecting their additional materials and processing requirements.

Delivery charges increase proportionally with distance from the batch plant. Most suppliers establish delivery zones with corresponding fuel surcharges, and projects located beyond standard service areas may incur substantial additional fees. Furthermore, suppliers often impose minimum order requirements, typically 1 to 3 cubic yards, and charge short-load fees for orders below these thresholds.

Timing also affects pricing. Weekend deliveries, holiday pours, and after-hours service generally cost 20-50% more than standard weekday rates. Additionally, market conditions influence pricing, with material costs fluctuating based on cement availability, fuel prices, and seasonal demand patterns. Houston experiences peak concrete demand during spring and fall when weather conditions optimize construction activity

How Do Houston’s Top Ready Mix Suppliers Ensure Quality?

Quality assurance separates exceptional ready mix concrete suppliers from mediocre providers. Leading Houston suppliers implement comprehensive quality management systems encompassing raw material testing, mix design verification, production monitoring, and delivered product sampling.

Aggregate testing occurs regularly to verify gradation, cleanliness, and absence of deleterious substances. Cement undergoes chemical analysis to confirm compliance with ASTM specifications, while water sources are tested for chloride content and other impurities that could compromise concrete performance. Additionally, admixtures receive batch-to-batch verification to ensure consistency and compatibility.

During production, computerized batching systems accurately proportion ingredients within tight tolerances, typically ±1% for cement and ±2% for aggregates. Automated moisture sensors continuously monitor aggregate moisture content, adjusting mix water accordingly to maintain consistent slump and water-cement ratio. Furthermore, batch records are electronically stored, providing complete traceability and facilitating quality audits.

Reputable suppliers also conduct field testing of delivered concrete, including slump tests, air content measurements, and cylinder samples for compressive strength verification. These tests ensure that concrete arriving at your job site meets specified requirements and provides documentation for quality assurance records.

What Questions Should You Ask Potential Ready Mix Suppliers?

Before committing to a ready mix concrete supplier, ask specific questions about their capabilities and service quality. Begin by inquiring about their service area and estimated delivery times to your project location. Reliable suppliers should provide accurate delivery times and consistently deliver on time.

Next, talk about mix design options and technical support. Inquire whether the supplier has qualified concrete technologists available for consultations and site visits. Inquire about their experience with applications similar to yours, and ask for sample mix designs with performance data.

To ensure pricing transparency, request detailed quotes that include base concrete costs, delivery charges, fuel surcharges, and any additional fees. Clarify cancellation policies, short-load charges, and overtime rates to avoid unexpected costs. Also, confirm the minimum order quantities and whether partial loads are acceptable.

Finally, look into the supplier’s safety record and environmental practices. Inquire about driver training programs, DOT compliance, and occupational safety statistics. Inquire about sustainability initiatives such as supplementary cementitious materials, recycled water systems, and carbon-reduction strategies.

How Has Technology Transformed Houston’s Ready Mix Concrete Industry?

Technological advancement continues revolutionizing the ready mix concrete industry in Houston. Modern suppliers leverage sophisticated software platforms that integrate order management, dispatching, GPS tracking, and customer communication. These systems enable real-time visibility into truck locations, estimated arrival times, and delivery status updates accessible via mobile apps or web portals.

Advanced batching technology ensures unprecedented accuracy and consistency. Automated plants equipped with moisture probes, digital scales, and programmable logic controllers eliminate human error while maintaining detailed production records. Moreover, some Houston suppliers have adopted mobile batching plants that can be deployed directly to large project sites, minimizing transportation time and maximizing concrete freshness.

Telematics systems installed in mixer trucks provide valuable operational data, including drum rotation speed, mixing time, and concrete temperature. This information helps drivers optimize delivery procedures while enabling dispatch personnel to make informed routing decisions. Additionally, electronic ticketing systems eliminate paperwork, accelerate processing, and improve record accuracy.

Innovation extends to concrete formulations as well. Houston suppliers increasingly offer smart concretes incorporating self-healing technologies, embedded sensors for structural health monitoring, and ultra-high-performance formulations achieving compressive strengths exceeding 20,000 PSI. These advanced products address demanding applications while demonstrating the industry’s commitment to continuous improvement.

Making a Houston Ready Mix Concrete Decision?

Selecting the right ready mix concrete supplier in Houston TX directly impacts your project’s success, timeline, and budget. By partnering with established suppliers offering comprehensive technical support, proven quality systems, reliable delivery, and competitive pricing, you position your project for optimal outcomes. Remember that the lowest price doesn’t always deliver the best value—factor in quality, service, and expertise when making your decision.

Houston’s construction market offers numerous ready mix concrete options, from large national suppliers to specialized local providers. Take time to evaluate multiple suppliers, check references, visit batch plants if possible, and establish clear communication channels before placing your first order. The effort invested in supplier selection pays dividends through smoother project execution, reduced delays, and superior concrete performance that stands the test of time.